Machine tools are the backbone of modern manufacturing, revolutionizing efficiency and precision. This comprehensive guide explores the significance of machine tools, addresses common queries surrounding their usage, and examines their role in optimizing operations across various industries. Additionally, we’ll delve into the importance of geomembranes in safeguarding machine tool applications.

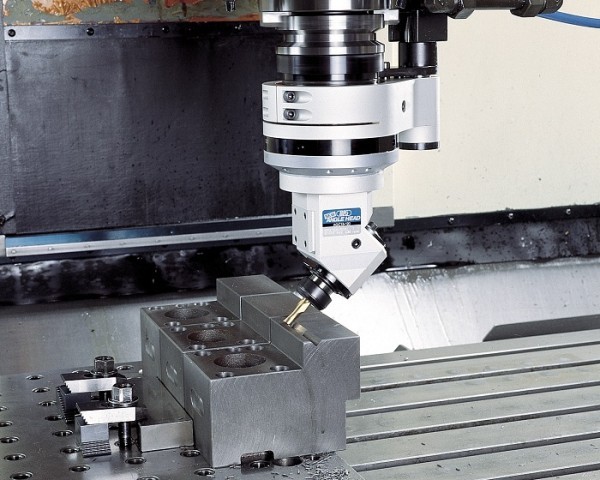

What are machine tools, and why are they pivotal in manufacturing?

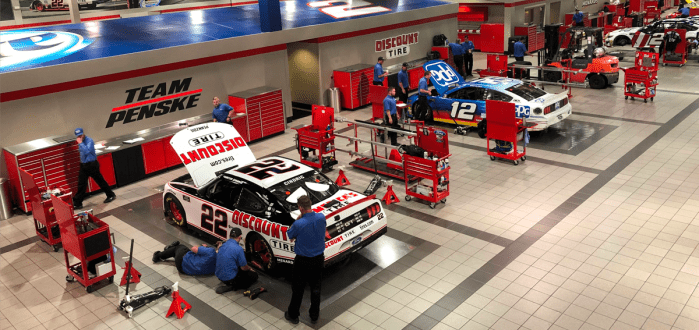

Machine tools encompass a wide spectrum of devices used to shape and manipulate metal and other rigid materials into specific forms. From lathes to milling machines, drills, and grinders, these tools are indispensable in manufacturing for their ability to produce intricate components with unparalleled precision and consistency. By automating processes and minimizing manual intervention, machine tools enhance productivity and reduce production costs.

How do machine tools enhance efficiency in industrial processes?

Machine tools streamline manufacturing operations by automating repetitive tasks and executing them with meticulous precision. For instance, CNC (Computer Numerical Control) machines enable programmable control over machining operations, ensuring uniform and precise results. By minimizing human error and optimizing cycle times, machine tools boost efficiency and throughput, ultimately driving cost-effectiveness and competitiveness.

What factors should be considered when selecting machine tools for a specific application?

Various factors influence the selection of machine tools for a particular application, including the material being processed, desired precision levels, production volume, and budget constraints. Additionally, considerations such as spindle speed, compatibility with cutting tools, and machine rigidity are crucial in determining suitability. Thorough evaluation of these factors is essential to ensure optimal performance and cost-effectiveness.

How do geomembranes contribute to the effectiveness of machine tool operations?

Geomembranes, typically crafted from resilient synthetic materials like polyethylene or PVC, serve as protective barriers in various industrial settings. In the context of machine tools, geomembranes are often utilized to prevent coolant leakage and contain fluids used in machining processes. By establishing a reliable barrier against corrosion and contamination, geomembranes safeguard the integrity of machine tools, prolonging their lifespan and minimizing maintenance downtime and associated costs.

Machine tools are indispensable assets in modern manufacturing, offering unparalleled precision, efficiency, and adaptability. From shaping raw materials to fabricating intricate components, these tools drive innovation and enhance competitiveness across diverse industries. By understanding their significance, selecting appropriate equipment, and implementing essential protective measures such as geomembranes, businesses can unlock the full potential of machine tools and optimize operational efficiency.