Rivet guns are indispensable tools across diverse industries, offering efficient and secure fastening solutions. Whether you’re in construction, automotive, or manufacturing, mastering the use of a rivet gun can significantly enhance your workflow and productivity. In this comprehensive guide, we’ll unravel the intricacies of rivet guns, exploring their applications, benefits, and essential tips for optimal performance.

What exactly is a rivet gun, and how does it function?

A rivet gun, also known as a pneumatic hammer, serves as a specialized tool designed to drive rivets into materials for fastening purposes. Its operational mechanism involves delivering a rapid succession of blows to the rivet’s tail, thereby deforming it against the workpiece and creating a sturdy joint. Rivet guns manifest in diverse types, encompassing manual, pneumatic, and hydraulic variants, each tailored for specific applications and operational environments.

Where do rivet guns predominantly find their applications?

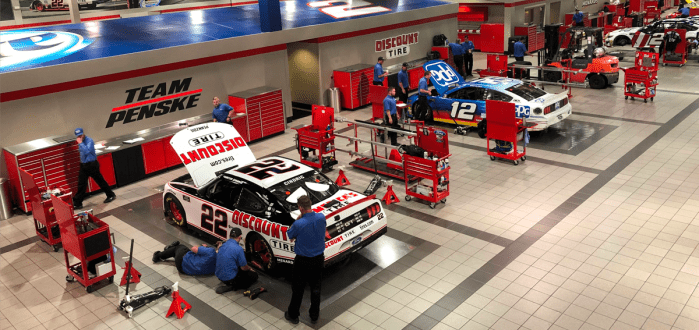

Rivet guns witness extensive employment across a plethora of industries for bonding materials ranging from metal and plastic to geocell. In the realm of construction, they emerge as pivotal for tasks such as structural steel erection, roofing, and sheet metal endeavors. Within automotive assembly lines, rivet guns prove indispensable for securely joining body panels and components. Furthermore, they play a crucial role in manufacturing processes, spanning the production of furniture, appliances, and aerospace components.

What distinct advantages do rivet guns offer over alternative fastening methods?

One of the key advantages of rivet guns lies in their capability to forge durable, permanent joints devoid of the necessity for access to the backside of the workpiece. Unlike screws or bolts, which necessitate nuts and washers, rivets engender a seamless, flush connection, ideal for scenarios prioritizing aesthetics and aerodynamics. Moreover, rivet guns boast swift installation and adaptability to confined spaces, augmenting efficiency and versatility.

How can I optimize the performance of my rivet gun?

Upholding regular maintenance serves as a cornerstone in ensuring peak performance and longevity of your rivet gun. Maintain the tool in a clean and well-lubricated state to thwart corrosion and mitigate wear on moving components. When cherry-picking rivets, opt for the suitable size and material commensurate with your application to attain the desired robustness and longevity. Additionally, adhere to proper safety protocols, encompassing the usage of protective gear like goggles and gloves, and refraining from surpassing the tool’s recommended operating pressure.

Rivet guns emerge as indispensable aids for fastening applications spanning myriad industries, proffering efficient, secure, and visually appealing joints. By comprehending the modus operandi of rivet guns, their applications, advantages, and maintenance requisites, you can unlock their full potential to streamline your operations and yield superlative outcomes. Whether you’re engrossed in erecting geocell structures or fusing metal components, a premium rivet gun stands as a prized asset capable of elevating your craftsmanship and output.