Valves are indispensable components across various industries, from manufacturing to energy production. These mechanical marvels efficiently control the flow of liquids, gases, and slurries within systems, maintaining optimal operational conditions. This article delves into the diverse applications and functions of valves while emphasizing the crucial role of geocells in specific scenarios.

Decoding Valves and Their Mechanisms

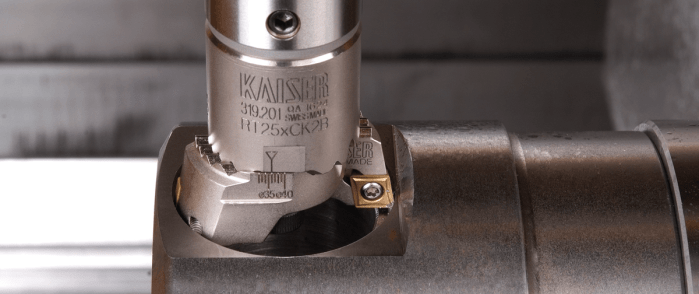

Valves, intricate mechanical devices, are designed to regulate, control, or direct fluid flow by opening, closing, or partially obstructing passages. Leveraging mechanisms like levers, gears, or solenoids, valves adjust their positions to perform these functions. The primary objective of valves is to oversee the flow of liquids or gases within systems, ensuring seamless and efficient processes.

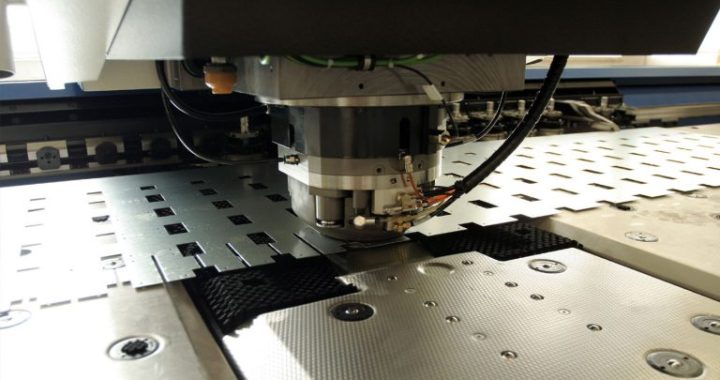

Exploring Valve Types and Their Applications

Valves come in various types, each tailored for specific applications. Common types include ball valves, gate valves, globe valves, and check valves. Ball valves are apt for on/off applications, while globe valves excel in flow regulation. Gate valves serve isolation purposes, and check valves prevent backflow. These versatile devices find applications across industries such as oil and gas, water treatment, pharmaceuticals, and manufacturing.

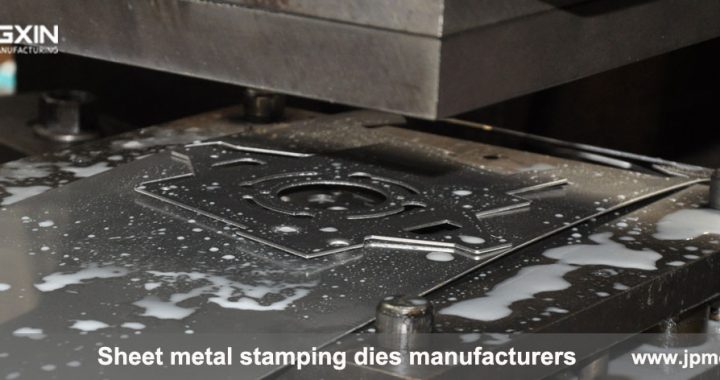

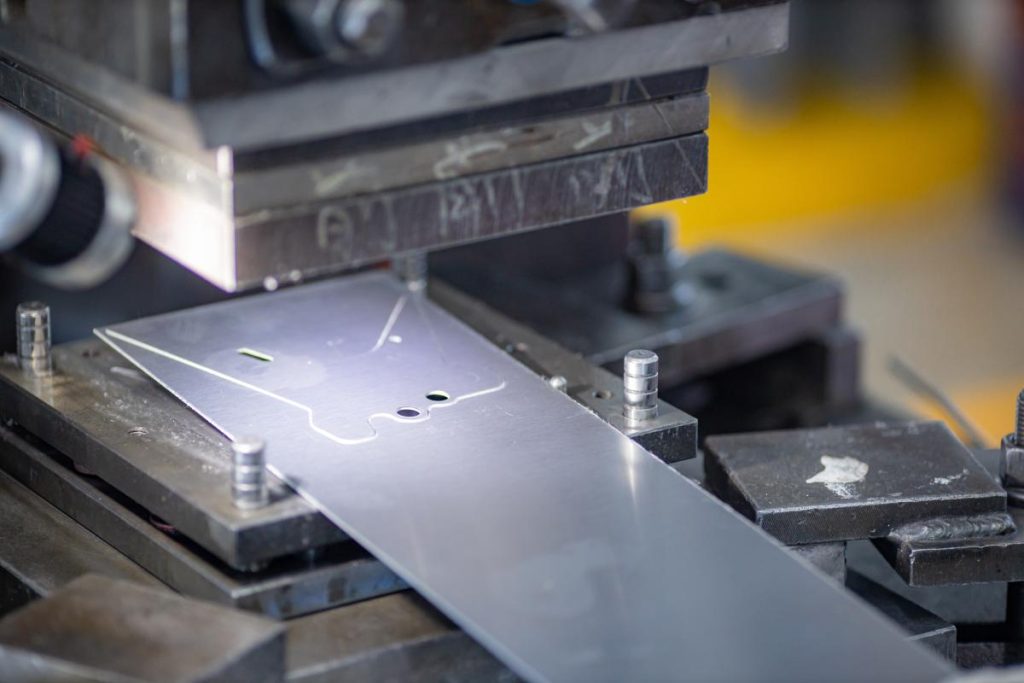

Valves at Work: Enhancing Industrial Processes

Integral to industrial processes, valves facilitate the control of fluid flow and pressure. In the oil and gas sector, valves regulate the flow of crude oil and natural gas through pipelines. Water treatment plants rely on valves to manage clean water distribution and wastewater control. In manufacturing, valves play a pivotal role in controlling fluid flow during production processes. Their precision ensures the efficiency and safety of these industrial operations.

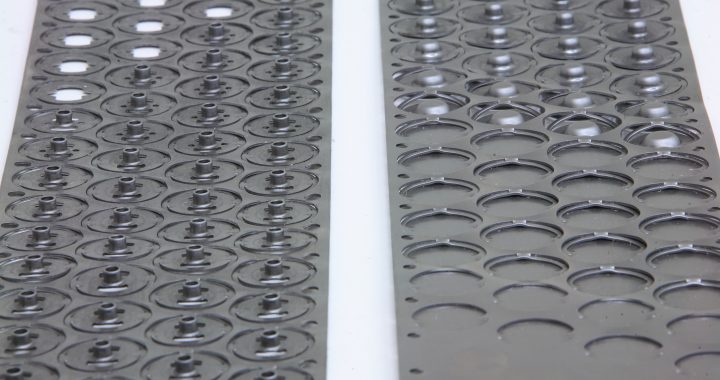

The Synergy of Valves and Geocells

Geocells, also known as cellular confinement systems, take the form of three-dimensional structures resembling honeycombs, crafted from high-density polyethylene. These geosynthetic materials offer support and stabilization to soil and aggregate, preventing erosion and enhancing load-bearing capacity. In the context of valves, geocells find applications in infrastructure projects, especially in the construction and reinforcement of levees and embankments. Geocells preserve the integrity of surrounding soil, particularly in erosion-prone areas, ensuring the stability of valve installations.

Valves: The Unsung Heroes of Industries

Valves emerge as unsung heroes in various industries, orchestrating smooth operations by expertly controlling fluid flow. Professionals in engineering, manufacturing, and maintenance benefit from understanding the diverse types of valves and their applications. Additionally, the incorporation of geocells in specific projects adds an extra layer of stability, showcasing the interconnectedness of various technologies for optimal functionality.